RECYCLING COMPOSITES

WH Lipex GmbH, part of the Woollard & Henry Group, is at the forefront of promoting sustainability through its recycling composites and transforming them into new fibres. The company’s commitment to environmental responsibility is evident in its active participation in the EU-funded SUSPENS project, dedicated to advancing sustainability practices.

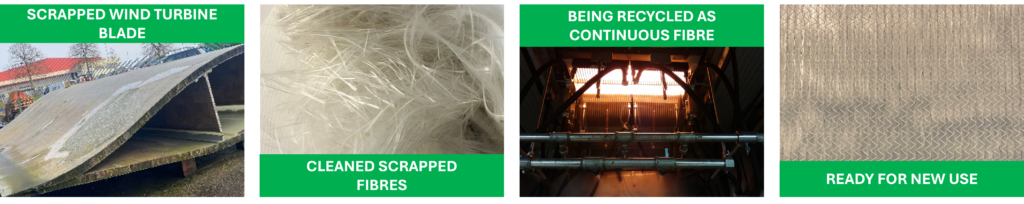

As part of the EU funded SUSPENS project, WH Lipex’ innovative approach plays an important role in recycling scrapped composites, particularly wind turbine blades, processing them into new continuous fibres and fabrics for composite applications. This comprehensive process involves the separation and cleaning of fibres, followed by melting and fibre forming.

First results of the new recycled fibre products were seen at JEC 2024 at our stand and the development will continue with first samples of finished products ready mid-2024. WH Lipex, in collaboration with its partners, sees that this pioneering recycling solution will contribute significantly to achieving circularity in composite materials.

WH LIPEX GmbH remains dedicated to serving its global customer base from its headquarters in Munich, Germany. Together WH Lipex and the Scottish based Woollard & Henry Group are leading the way in fostering a greener and more circular approach to composite materials worldwide.

WH Lipex focusing on sustainability

We are one of the Suspens partners tackling the challenge of reducing the environmental footprint of sandwich composite and hollow structures manufacture for the automotive, nautical leisure and aeronautics industries.

WH LIPEX WITH

PAMA AND WOOLLARD & HENRY

AT JEC PARIS

We want to thank all our partners and customers!

We will return in 2023!!!

JEC WORLD in Paris

3, 4, 5 Mai 2022

After 2 years of postponement…

WHLipex is flying there!

To meet us, please, call our Sales Department:

t.korhonen@lipex.de

Woollard & Henry and WHLipex in Guyana

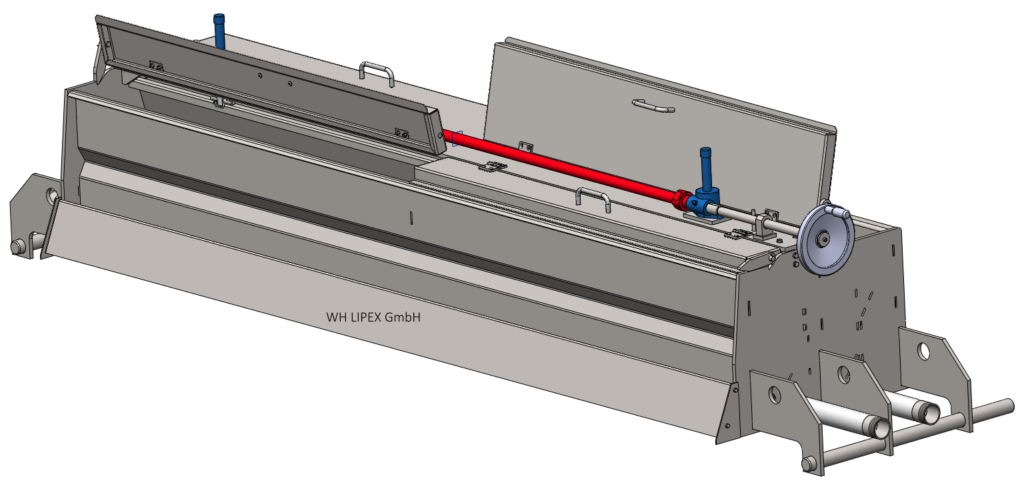

WH LIPEX INTRODUCES NEW IMPROVED RECYLING PLANT FOR RECYCLING OF GLASS FIBRE PRODUCTION WASTE

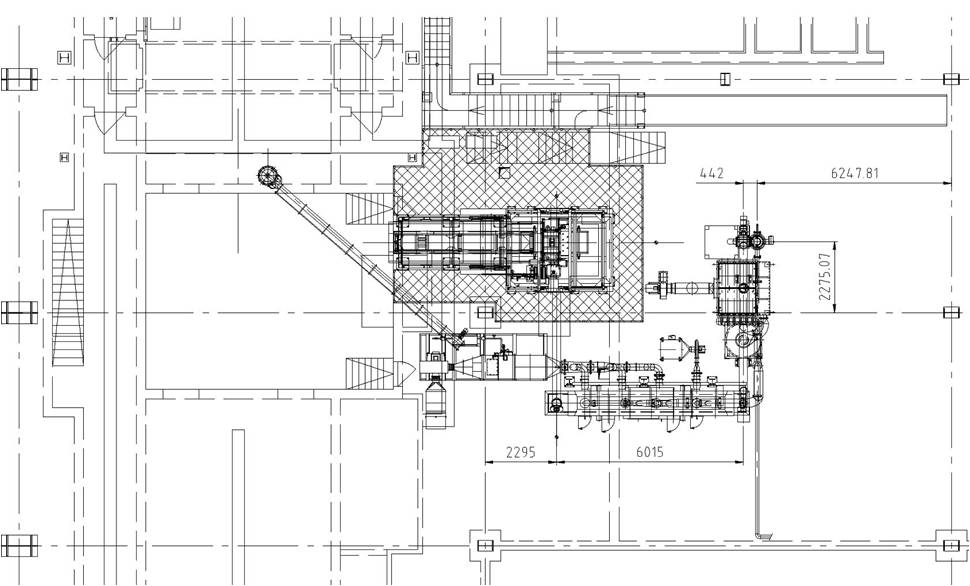

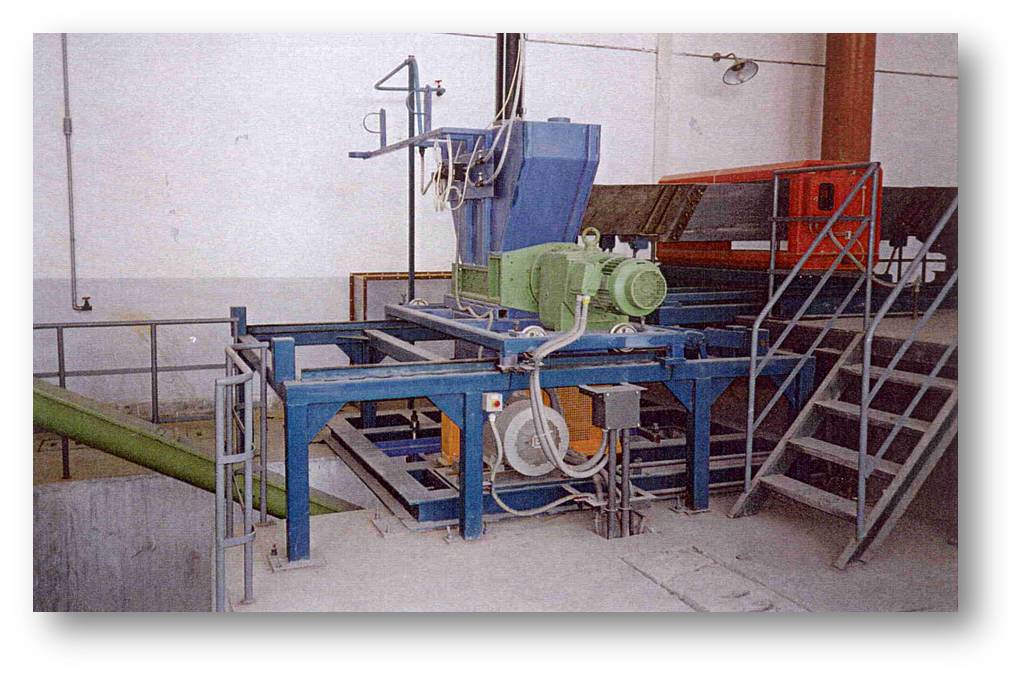

Due to the nature of the glass fibre production there is always some waste coming from fiber forming. WH Lipex recycling plant is designed to reduce the waste load from glass fibre plants and reduce overall cost by eliminating waste transport to outside of the plant. The waste can be recycled and fed back to the furnace as part of the raw material batch.

The recycling plant is customized to end user needs and can be designed with manual or automatic feeding of waste glass fibres.

WH Lipex has been supplying recycling plants for over 15 years and now introduces new improved plant.

The main advantages for the improved recycling plant are:

- Improved drying efficiency

- Improved filter efficiency

- Improved energy efficiency

- Improved cost savings for end users

The recycling plant can be installed easily to existing plants.

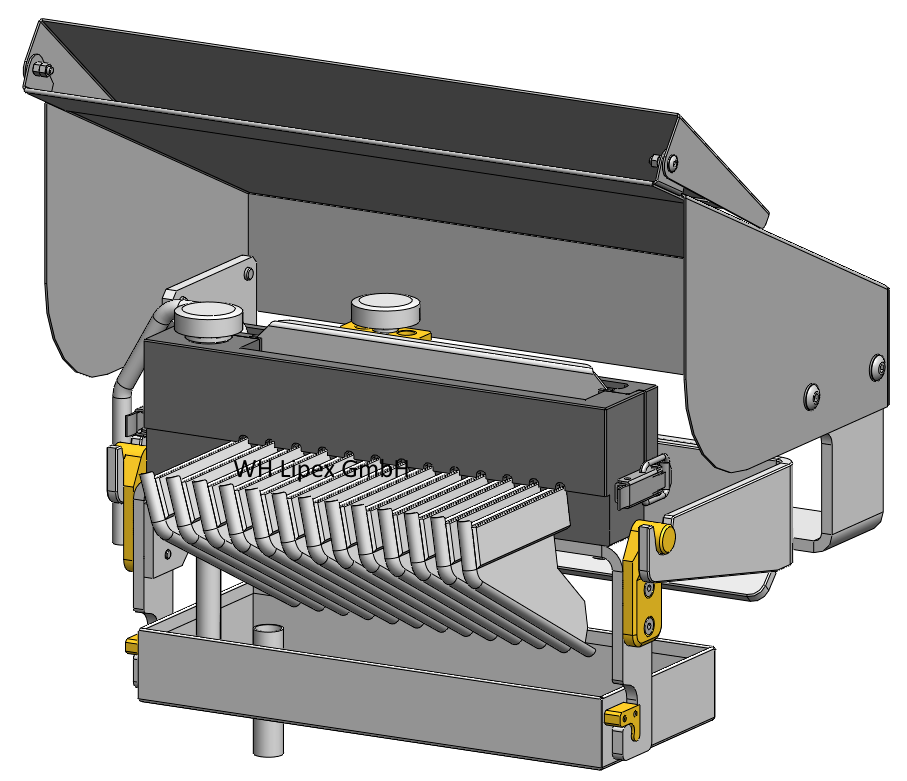

WE ARE INTRODUCING NEW FEATURES FOR OUR NON WOVEN GLASS FIBRE TISSUE LINE

Newly introduced and developed binder applicator for the nonwoven tissue line will give significant benefits for our customers. We have placed special emphasis on fast cleaning and good handling of the applicator. All internal parts can now be removed quickly and easily without the use of tools and can therefore be cleaned faster reducing production line downtime considerably. Furthermore, we were able to simplify the handling of the applicator considerably in order to adjust the applicator even faster and more precisely. The result is an accurate distribution and minimization of the binder consumption. This saves time and resources for our customers.

Our new filter inserts for the dryer can be easily changed during operation without the need for any additional tools. By pushing in the new filter insert “A”, the old filter insert “B” is pushed out. This ensures that the filter process is not interrupted at any time. This guarantees a constant high quality of the production. The filter mat can be produced inexpensively on the customers own production line.

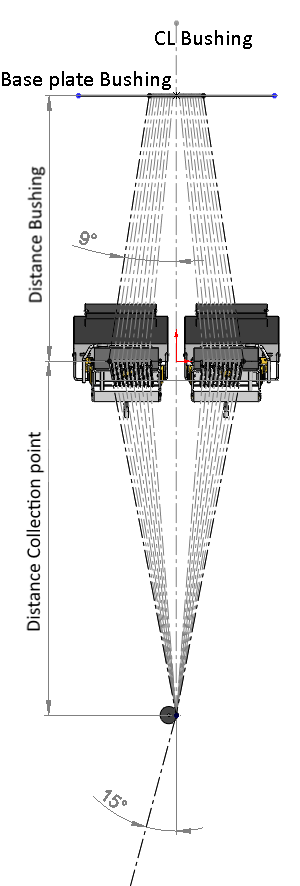

single fibRE applicator

Newly introduced and developed coating module, the single fibre applicator, allows coating individual glass fibres with wetting additives. On this single fibre applicator, the fibres are no longer in bundles on the applicator but individually displayed. This ensures that all individual filaments are better enclosed with wetting additive (sizing). This performance increases significantly the amount of wetting additive on the fibres and thus improves the bonding possibilities to the other materials in which the glass fibres are embedded.

Main advantages for this Applicator:

→ Increases the mechanical properties of the end product,

→ New possibilities for weight and cost reduction without losing mechanical properties for end products.

Need some more detailed information?

- lipex@lipex.de

- 0049 (0)89 800 9920

Ownership change for Lipex Engineering GmbH

Scottish engineering company Woollard & Henry has acquired the assets of the Lipex Engineering GmbH from Eniclay Group and formed a new company called WH LIPEX GmbH. This company as a part of Woollard & Henry will continue to serve international glass and basalt fibre industry.

LIPEX Anlagentechnik und Handel GmbH was originally founded in 1975 and has been a preferred supplier of machinery, equipment and technology for the production of industrial glass fibres. LIPEX is a specialized engineering service provider that conceptually plans both single production lines and complete manufacturing facilities or plants, also as general contractor for the production of industrial glass fibres and creates the necessary designs and provides technology. LIPEX has also strong experience in glass and sizing chemistry for both basalt and glass fibres. WH LIPEX GmbH will continue to provide its worldwide customers high quality service and technology in the field of glass fibre industry.

Woollard and Henry’s acquisition of LIPEX, follows the acquisition of a major shareholding in the German machine builders, Pama GmbH. The collaboration and new group structure will allow better access to product development and manufacturing facilities enabling Lipex customers to take advantage of the greater synergies while improving their business, which is one of the core values of the new company.

Woollard & Henry is Scottish based employee owned company founded in 1873. Main business sectors for W&H are paper and energy industry and with the acquisition of LIPEX allows W&H to further diverse it’s activities into glass and basalt fibres. With strong experience in specialty paper engineering W&H can help LIPEX improve their nonwoven tissue and chopped strand mat technology for the future.

Currently WH LIPEX GmbH is working on various projects in the Europe, Asia and Middle-East.

WH LIPEX GmbH will continue to serve customers worldwide from Puchheim, Munich area in Germany.